Articles Symptoms Of A Bad Crank Angle Sensor going viral

Your car’s engine is a complex system, and it relies on a number of sensors to function properly. One of these sensors is the crank angle sensor, which monitors the position of the crankshaft and sends this information to the engine’s computer. If the crank angle sensor fails, it can cause a number of problems, including engine stalling, misfiring, and reduced power.

Symptoms of a Bad Crank Angle Sensor

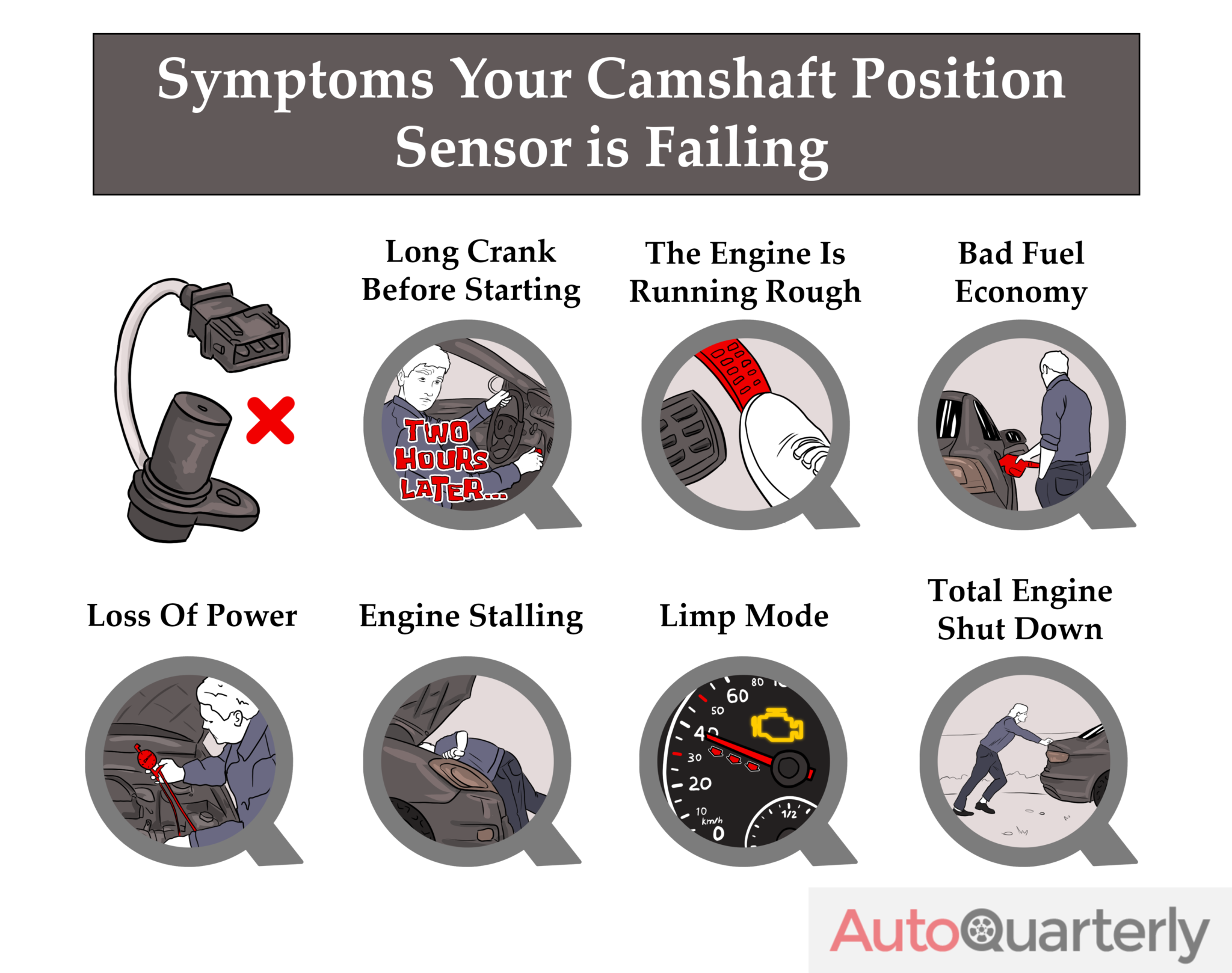

There are a number of symptoms that can indicate a bad crank angle sensor. These symptoms include:

Engine stalling: A bad crank angle sensor can cause the engine to stall, especially when the engine is idling or at low speeds.

Misfiring: A bad crank angle sensor can also cause the engine to misfire, which can lead to rough idling, reduced power, and increased fuel consumption.

Reduced power: A bad crank angle sensor can also cause the engine to lose power, especially when the engine is under load.

What is a Crank Angle Sensor?

The crank angle sensor is a small, electronic device that is mounted on the engine block. It uses a magnetic field to detect the position of the crankshaft, and it sends this information to the engine’s computer. The computer uses this information to control the timing of the ignition and fuel injection systems.

Without a functioning crank angle sensor, the engine will not be able to run properly. The engine may stall, misfire, or lose power. In some cases, a bad crank angle sensor can even prevent the engine from starting.

History and Myth of Crank Angle Sensor

The crank angle sensor was first developed in the early 1980s as a replacement for the older distributor-based ignition systems. These systems were less accurate and reliable than the crank angle sensor, and they were also more difficult to maintain.

Since its introduction, the crank angle sensor has become a standard feature on most modern vehicles. It is a reliable and accurate way to measure the position of the crankshaft, and it is essential for the proper functioning of the engine.

Hidden Secret of Crank Angle Sensor

The crank angle sensor is a relatively simple device, but it plays a vital role in the operation of the engine. Here are a few of the hidden secrets of the crank angle sensor:

It is used to control the timing of the fuel injection system. The fuel injection system is responsible for delivering the right amount of fuel to the engine at the right time. The crank angle sensor provides the computer with the information it needs to time the fuel injection so that it occurs at the optimum moment for combustion.

Recommendation of Crank Angle Sensor

If you are experiencing any of the symptoms of a bad crank angle sensor, it is important to have the sensor checked by a qualified mechanic. Replacing a bad crank angle sensor is a relatively simple and inexpensive repair, and it can save you a lot of money in the long run.

Here are a few tips for choosing a crank angle sensor:

Choose a sensor that is made by a reputable manufacturer.

Make sure that the sensor is compatible with your vehicle’s make and model.

Read the reviews of the sensor before you buy it.

Crank Angle Sensor: The Basics

The crank angle sensor is a device that measures the angular position of the crankshaft in an internal combustion engine. This information is used by the engine’s electronic control unit (ECU) to determine the timing of the ignition and fuel injection systems.

The crank angle sensor is typically mounted on the engine block or cylinder head, and it uses a variety of technologies to measure the crankshaft’s position. Some crank angle sensors use a magnetic pickup to detect the passage of a ferrous target on the crankshaft, while others use an optical sensor to detect the position of a reflective target.

Tips of Crank Angle Sensor

Here are some tips for getting the most out of your crank angle sensor:

Keep the sensor clean. A dirty sensor can cause inaccurate readings, which can lead to problems with the engine’s performance.

Inspect the sensor regularly. Look for any signs of damage, such as cracks or loose wires. If you find any damage, replace the sensor immediately.

Replace the sensor according to the manufacturer’s recommendations. Most crank angle sensors should be replaced every 60,000 to 100,000 miles.

Crank Angle Sensor: Troubleshooting

If you are experiencing problems with your engine’s performance, the crank angle sensor may be the culprit. Here are some tips for troubleshooting a bad crank angle sensor:

Check the sensor’s electrical connections. Make sure that the sensor is properly connected to the engine’s wiring harness. If the connections are loose or corroded, clean them and reconnect the sensor.

Test the sensor’s resistance. Use a multimeter to measure the resistance between the sensor’s terminals. The resistance should be within the manufacturer’s specifications.

Fun Facts of Crank Angle Sensor

Here are some fun facts about crank angle sensors:

The crank angle sensor is one of the most important sensors in the engine. It provides the ECU with critical information that is used to control the engine’s timing.

Crank angle sensors are very reliable devices. However, they can fail over time, and it is important to know the symptoms of a bad crank angle sensor.

How to Symptoms Of A Bad Crank Angle Sensor

If you are experiencing any of the symptoms of a bad crank angle sensor, it is important to have the sensor checked by a qualified mechanic. Replacing a bad crank angle sensor is a relatively simple and inexpensive repair, and it can save you a lot of money in the long run.

Here are the steps on how to replace a crank angle sensor:

Locate the crank angle sensor. The sensor is typically located on the engine block or cylinder head.

Disconnect the sensor’s electrical connector.

What if Symptoms Of A Bad Crank Angle Sensor

If you are experiencing any of the symptoms of a bad crank angle sensor, it is important to have the sensor checked by a qualified mechanic. Replacing a bad crank angle sensor is a relatively simple and inexpensive repair, and it can save you a lot of money in the long run.

Here are the consequences of not replacing a bad crank angle sensor:

The engine may stall or misfire.

The engine may lose power.

Listicle of Symptoms Of A Bad Crank Angle Sensor

Here is a listicle of the symptoms of a bad crank angle sensor:

Engine stalling

Misfiring

Reduced power

Rough idling

Increased fuel consumption

Question and Answer

Here are some frequently asked questions about crank angle sensors:

Q: What are the symptoms of a bad crank angle sensor?

A: The symptoms of a bad crank angle sensor include engine stalling, misfiring, reduced power, rough idling, and increased fuel consumption.

Q: How can I test a crank angle sensor?

A: You can test a crank angle sensor by measuring its resistance with a multimeter. The resistance should be within the manufacturer’s specifications.

Q: How much does it cost to replace a crank angle sensor?

A: The cost to replace a crank angle sensor varies depending on the make and model of your vehicle. However, the average cost is between $100 and $200.

Q: How often should I replace my crank angle sensor?

A: Most crank angle sensors should be replaced every 60,000 to 100,000 miles.

Conclusion of Symptoms Of A Bad Crank Angle Sensor

The crank angle sensor is a critical component of the engine’s timing system. A bad crank angle sensor can cause the engine to stall, misfire, or lose power. If you are experiencing any of the symptoms of a bad crank angle sensor, it is important to have the sensor checked by a qualified mechanic. Replacing a bad crank angle sensor is a relatively simple and inexpensive repair, and it can save you a lot of money in the long run.